Our Products

- Home

- Products

Introducing Best products with high Quality and Competitve Package

About Technical Consulting

Reliable engineering takes many forms.

In sed nisl leo elit ultricies mauris. Sed nibh natoque eleifend mi ante. Magnis vivamus maximus senectus lacus inceptos. Feugiat natoque mi nascetur.

Adipiscing imperdiet eget vel. Massa ligula sociosqu a. Mus viverra ut ornare tempor dictumst eros habitant.

When you need experience, we have it covered.

Tempus ut purus nulla in. Pulvinar volutpat ante mus ultrices nunc habitasse. Pulvinar egestas venenatis sed duis. Dui odio parturient volutpat lobortis leo.

Potenti conubia libero massa eget senectus mollis. Augue consequat ipsum taciti dolor felis. Pretium at per mattis. Vivamus tellus purus aenean duis. Fames tortor dictumst scelerisque cursus condimentum. Fames nunc potenti adipiscing aptent. Hac dapibus laoreet mattis condimentum commodo consectetur class. Orci diam egestas adipiscing litora dui in sociosqu.

Tempus ut purus nulla in. Pulvinar volutpat ante mus ultrices nunc habitasse. Pulvinar egestas venenatis sed duis. Dui odio parturient volutpat lobortis leo.

Service Group

We made passion our raw material.

Acoustic consulting

Neque ad vitae felis augue aenean finibus maecenas adipiscing lacinia

Advanced technology and research

Neque ad vitae felis augue aenean finibus maecenas adipiscing lacinia

Geotechnics

Neque ad vitae felis augue aenean finibus maecenas adipiscing lacinia

Audio visual and multimedia

Neque ad vitae felis augue aenean finibus maecenas adipiscing lacinia

Computational fluid dynamics

Neque ad vitae felis augue aenean finibus maecenas adipiscing lacinia

Geographic information systems

Neque ad vitae felis augue aenean finibus maecenas adipiscing lacinia

Hydrogeology

Neque ad vitae felis augue aenean finibus maecenas adipiscing lacinia

Wind engineering

Neque ad vitae felis augue aenean finibus maecenas adipiscing lacinia

Latest Project

Awesome Project from this Service.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Wind energy at DePuy Synthes

Let's start your project to be realize.

We planted our roots with a commitment to earning your trust and protecting lives, property, and prestige.

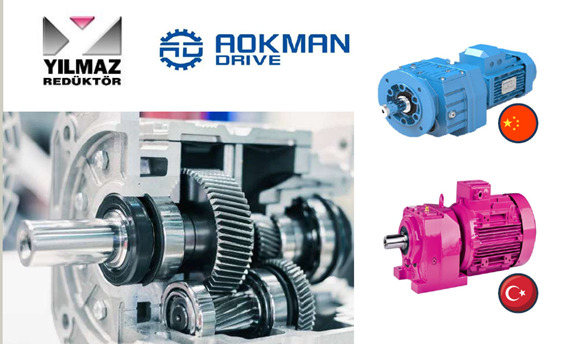

A- Motors

1- ITALIAN ELECTRIC MOTORS:

- High performance & High efficiency

- Compactness and flexibility

- Suitable for running with inverter

- Reduced environmental impact and energy saving

- low noise, low vibration, energy saving, long service life.

- Frequency: 220/380V 60Hz

- Power: (0.25KW~22KW)

- Poles: (2P, 4P)

- Three-phase motors and brake motors with high low noise, progressivity

- and dynamics. They are specifically suitable for coupling with gear motors

- minimizing the dynamic overloads deriving from starting and baking

phases and maintaining a very good braking torque value.

2- TURKEY ELECTRIC MOTORS:

- High performance & High efficiency

- Compactness and flexibility

- Suitable for running with inverter

- Reduced environmental impact and energy saving

- low noise, low vibration, energy saving, long service life.

- Frequency: (220/380: 380/660V 60Hz)

- Power: (0.25KW~250KW)

- Poles: (2P,4P,6P,8P)

- Three-phase motors and brake motors with high low noise, progressivity

- and dynamics. They are specifically suitable for coupling with gear motors

- minimizing the dynamic overloads deriving from starting and baking

- phases and maintaining a very good braking torque value.

3- CHINA ELECTRIC MOTORS:

- High performance & High efficiency

- Compactness and flexibility

- Suitable for running with inverter

- Reduced environmental impact and energy saving

- low noise, low vibration, energy saving, long service life.

- Frequency: (220/380: 380/660V 60Hz)

- Power: (0.25KW~250KW)

- Poles: (2P,4P,6P)

- Three-phase motors and brake motors with high low noise, progressivity

and dynamics. They are specifically suitable for coupling with gear motors

minimizing the dynamic overloads deriving from starting and baking

phases and maintaining a very good braking torque value.

B- GEARBOXES

1- HELICAL GEARBOX:

- Rated Power: 0.18kW~160kW

- Max. Torque: Up to 18000N.m

- Gear Arrangement: Hardened Helical Gears

- Shafts Position: Inline or Parallel

- Ratio: 1.3~289.6

FEATURES:

- Compact structure, modular design

- Single-stage, two-stage and three-stage sizes

- High reduction ratio and torque density

- Long service life

COMPONENTS:

- Housing: Cast Iron

- Gears: Helical Gears

APPLICABLE MOTORS:

- Single Phase AC Motor, Three

Phase AC Motor

- Brake Motors

- Inverter Motors

- Multi-speed Motors

- Explosion-proof Motor

- Roller Motor

OUTPUT CONFIGURATIONS:

- Solid Shaft Output

INSTALLATION:

- Foot Mounted

- Flange Mounted

LUBRICATION:

- Oil-bath and Splash Lubrication

COOLING:

- Natural Cooling

2- WORM GEARBOX

- Rated Power:0.06KW~15KW

- Rated Torque: 1. 8~1760N.m

- Rated Ratio:5~100

- Gear Arrangement: Worm Wheel & Worm

Shaft

- Housing: Aluminum Alloy or Cast Iron

- Shafts Position: Right Angle

- COMPONENTS:

- Housing: Die-cast Aluminum Alloy Gearbox

(RV025~RV090)

- Cast Iron Gearbox (RV110~RV150)

- Worm Wheel: Wearable Tin (Stannum) Bronze

Alloy, Aluminum Bronze Alloy

- WORM SHAFT:

- 20Cr Steel, carburizing, quenching, grinding,

- Surface hardness 56-62HRC, 0.3-0.5mm

remaining carburized layer after precise

grinding

- INPUT CONFIGURATIONS:

- Equipped with Electric Motors (AC Motor,

Brake Motor, DC Motor, Servo Motor)

- IEC B5/B14 Motor Flange

- NEMA C Frame Motor Flange

- Solid Shaft Input

- OUTPUT CONFIGURATIONS:

- Keyed Hollow Shaft Output

- Hollow Shaft with Output Flange

- Plug-in Solid Shaft Output

OPTIONS:

- Worm Shaft Rear Extension, Single Output

Shaft

- Double Output Shaft, Output Flange, Torque

Arm, Dust Cover

3- GEARBOX PAINTING

Aluminum Alloy Gearbox:

After Shot Blasting, Anticorrosion Treatment and Phosphating, Paint with the Color of

RAL 5010 Gentian Blue or RAL 7035 Light Grey

CAST IRON GEARBOX:

After Painting with Red Antirust Paint, Paint with the Color of RAL 5010 Gentian Blue

MODELS:

- Hollow Shaft Input with IEC-normalized Motor Flange

- RV025~RV150

- Solid Shaft Input

- RV025~RV150

FEATURES:

- Quality aluminum alloy gear box, light weight and not rust

- 2 optional worm wheel materials: Tin (Stannum) bronze or aluminum bronze alloy

- Standard parts and very flexible for shaft configurations and motor flange interface

- Several optional mounting options

- Low noise, High efficiency in heat dissipation

INSTALLATION:

- Flange Mounted

- Foot Mounted

- Torque Arm Mounted

LUBRICATION:

- Grease Lubrication

- Oil-bath and Splash Lubrication

COOLING:

- Natural Cooling

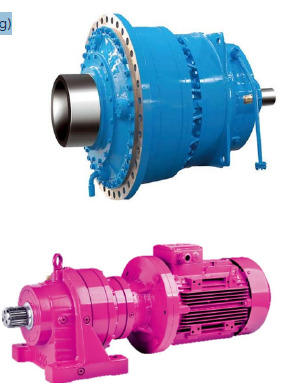

C- PLANETARY GEARBOX:

COMPONENTS:

- Housing: Nodular Cast Iron / Ductile Iron

- Gear set: Planetary Gear Set (Epicyclic Gearing)

- Input Configurations:

Integrated with Electric Motors (AC Motors,

Hydraulic Motors, Geared Motors)

IEC-normalized Motor Flange & Motor Adaptor

- Output Configurations:

Keyed Solid Shaft Output

- Involute Splined Solid Shaft Output

(GB or DIN Standard)

- Involute Splined Hollow Shaft Output

(GB or DIN Standard)

- Hollow Shaft Output with Shrink Disc

- Optional Accessories:

- Gear Unit Base for Horizontal Mounted

- Torque Arm, Torque Shaft Support

- Motor Mounting Bracket

- Dip Lubrication Compensation Oil Tank

- Forced Lubrication Oil Pump

- Cooling Fan, Auxiliary Cooling Devices

Models:

- P2N – 2 Stage Planetary Gear Set, Coaxial

- P2L – 2 Stage Planetary Gear Set Integrated with

Spiral Bevel Gear Pair, Right Angle

- P2S – 2 Stage Planetary Gear Set Integrated with

Helical Gear Pair, Parallel Shaft

- P2K – 2 Stage Planetary Gear Set Integrated with

Helical Gear Pair & Bevel Gear Pair, Right Angle

- P3N – 3 Stage Planetary Gear Set, Coaxial

- P3S – 3 Stage Planetary Gear Set Integrated with

Helical Gear Pair, Parallel Shaft

- P3K – 3 Stage Planetary Gear Set Integrated with

Helical Gear Pair & Bevel Gear Pair, Right Angle

Frame Sizes: 9, 10, 11, … 34, 35, 36 (exclude 15)

COMPONENTS:

- Housing: Nodular Cast Iron / Ductile Iron

- Gear set: Planetary Gear Set (Epicyclic Gearing)

- Input Configurations:

Integrated with Electric Motors (AC Motors,

Hydraulic Motors, Geared Motors)

IEC-normalized Motor Flange & Motor Adaptor

- Output Configurations:

Keyed Solid Shaft Output

- Involute Splined Solid Shaft Output

(GB or DIN Standard)

- Involute Splined Hollow Shaft Output

(GB or DIN Standard)

- Hollow Shaft Output with Shrink Disc

- Optional Accessories:

- Gear Unit Base for Horizontal Mounted

- Torque Arm, Torque Shaft Support

- Motor Mounting Bracket

- Dip Lubrication Compensation Oil Tank

- Forced Lubrication Oil Pump

- Cooling Fan, Auxiliary Cooling Devices

Models:

- P2N – 2 Stage Planetary Gear Set, Coaxial

- P2L – 2 Stage Planetary Gear Set Integrated with

Spiral Bevel Gear Pair, Right Angle

- P2S – 2 Stage Planetary Gear Set Integrated with

Helical Gear Pair, Parallel Shaft

- P2K – 2 Stage Planetary Gear Set Integrated with

Helical Gear Pair & Bevel Gear Pair, Right Angle

- P3N – 3 Stage Planetary Gear Set, Coaxial

- P3S – 3 Stage Planetary Gear Set Integrated with

Helical Gear Pair, Parallel Shaft

- P3K – 3 Stage Planetary Gear Set Integrated with

Helical Gear Pair & Bevel Gear Pair, Right Angle

Frame Sizes: 9, 10, 11, … 34, 35, 36 (exclude 15)

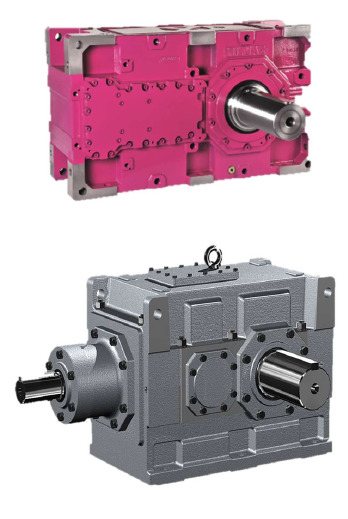

D- INDUSTRIAL GEARBOX

COMPONENTS:

- Housing: Casting Iron Box

- Gears:

Hardened Helical Gears (MC.H Series

Parallel Shaft Gearbox)

Hardened Helical Bevel Gears (MC.B

Series Right Angle Gearbox).

- Shafts:

Parallel Shafts (MC.H Series).

Orthogonal Shafts (MC.B Series).

Output Shaft: Solid Shaft, Hollow Shaft.

- Modular Accessories:

Shrink Disk, Mounting Flange, Motor

Flange, Cooling Fan, Torque Arm,

Double Input Shaft.

MODELS:

Total 8 Model Sizes: MC02 ~ MC09

FEATURES:

- Optional mounted by any one side

of six sides.

- Compact structure, light weight.

- Rigid welded box structure, heavy

duty and high load capacity.

- Modular scheme and design for

special conditions, adapting to the

diverse needs. 5. 2 stage or 3 stage

drive gearbox.

APPLICATIONS:

Crushing, Mixing, Building Materials, Lifting, Bulk

Material Handling, Chemical, Food Processing, Wood,

Paper, and Environmental Protection Industries.

INSTALLATION:

Mounting Type: Horizontal Mounting, Vertical

Mounting, Upright Mounting Installation Method: Foot

Mounted, Torque Arm Mounted.

LUBRICATION METHOD:

Splash lubrication – Low oil level (Horizontal Mounting)

Immersion lubrication – High oil level (Vertical Mounting,

Upright Mounting).

LUBRICATION:

Selecting the appropriate lubrication method according

to the lubricating oil level.

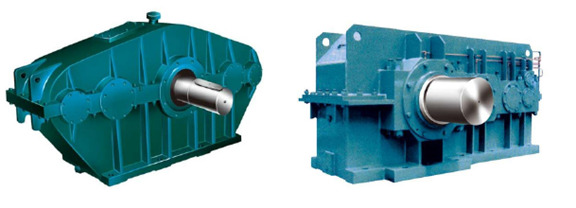

D- INDUSTRIAL GEARBOX

Large Metallurgical Cranes are special cranes for metallurgy and mainly applied in

metal smelting, rolling and thermal processing. Metallurgy cranes have been

developed a full series from 80t to 480t and AOKMAN® has developed a

complete series gearbox for supporting the cranes. AOKMAN® Large Crane

Gearboxes are also suitable for hydropower crane applications.

MAIN FEATURES:

- Specially designed and optimized for large cranes, high reliability and usability

- Customizable sizes and configurations according to the large cranes application

Technical Parameters:

Input Power: 200kW~800kW

Input Speed: ≤1000rpm

Ratio: 20~100

Please consult AOKMAN® technical engineers for detailed parameters.

Applications:

Metallurgy Cranes: Bridge Cranes, Gantry Cranes

Hydropower Cranes: Bridge Cranes, Gantry Cranes, Tower Cranes

Flip Machine Gearboxes are specially developed

and designed for steel plate, heavy plate flipping

applications in steel rolling production lines.

MAIN FEATURES:

- Specially designed and optimized for steel

plate flipping

- Large load capacity, high reliability and

usability, and the output shaft can withstand

large radial force

- Customizable sizes and configurations

Technical Parameters:

Gearboxes Housing: Steel Plate Welding

Steel Plate Width: 3000~5500mm

Input Speed: 500~1500rpm

Ratio: 100~400

Torque: Maximum 1500kN.m

Please consult AOKMAN® technical

engineers for detailed parameters.

Applications:

Steel plate flipping.

Heavy plate flipping.

Mining, Metallurgy, Cement, Energy,

Building Materials, Lifting and Transport.